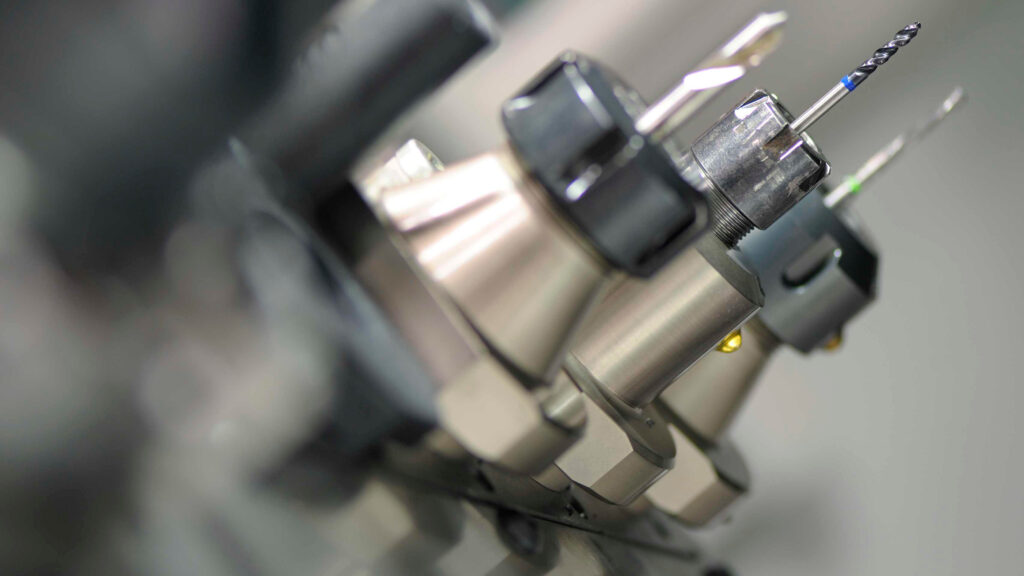

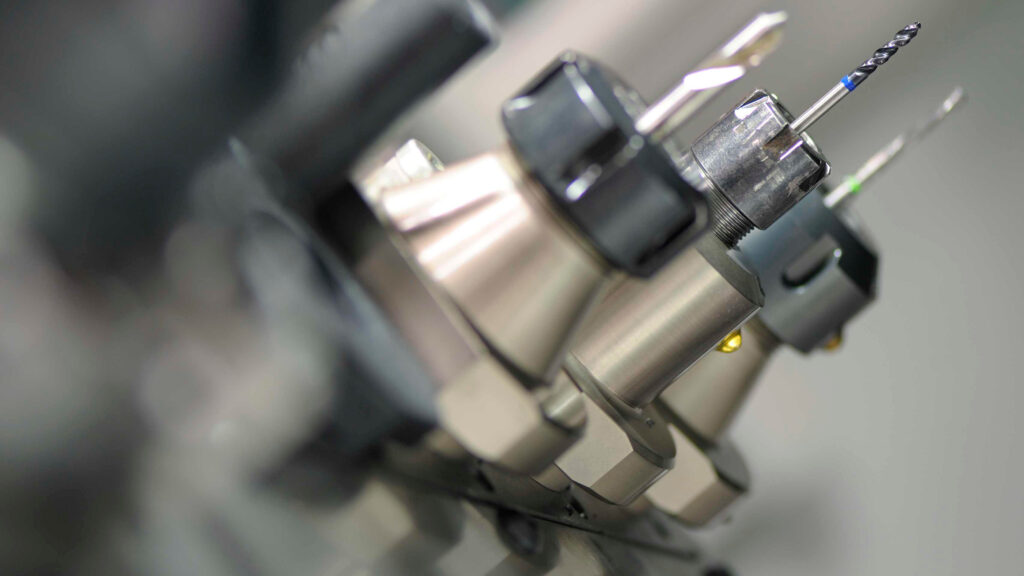

Production

WITH MODERN MACHINES AND VERY COMPETENT AND EXPERIENCED STAFF, WE ARE READY TO MEET TODAY'S REQUIREMENTS FOR QUALITY AND DELIVERY PRECISION.

Our aim is to always be at the forefront when it comes to the latest developments and, together with our customers, create long-term relationships that result in effective solutions for our customers.

Production

WITH MODERN MACHINES AND VERY COMPETENT AND EXPERIENCED STAFF, WE ARE READY TO MEET TODAY'S REQUIREMENTS FOR QUALITY AND DELIVERY PRECISION.

Our aim is to always be at the forefront when it comes to the latest developments and, together with our customers, create long-term relationships that result in effective solutions for our customers.

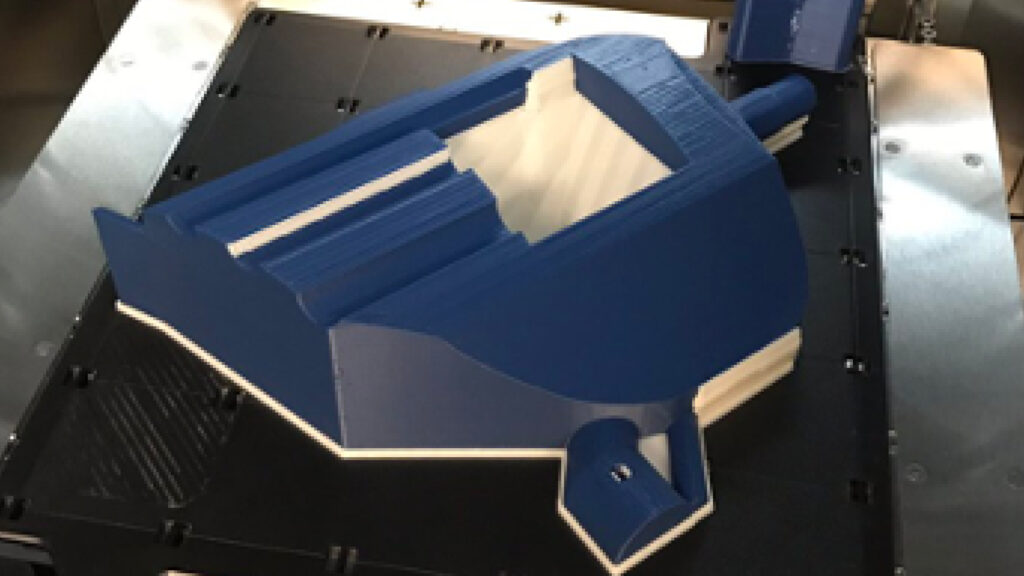

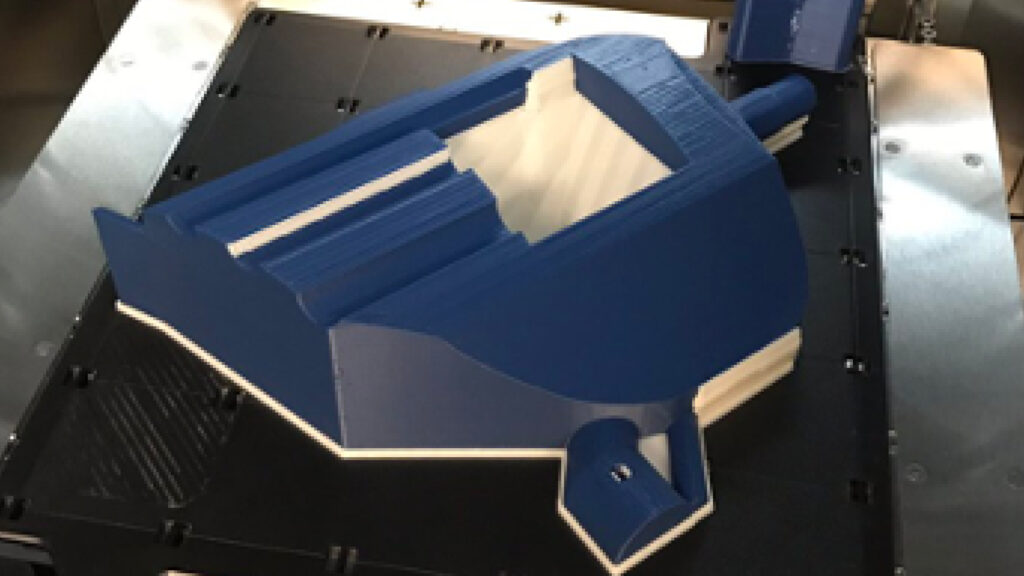

3D printing

MERX SVENSKA AB BROADENS OUR CUSTOMER OFFER AND CAN NOW OFFER ADDITIVE MANUFACTURING IN A STRATASYS F170 WITH FDM TECHNOLOGY.

FDM is a manufacturing method where strong construction plastic is melted down and then laid out layer by layer. With FDM technology comes durable and strong prints that are suitable for application areas where you have to manufacture e.g. robust prototypes or lightweight parts in strong construction thermoplastics.

3D printing

MERX SVENSKA AB BROADENS OUR CUSTOMER OFFER AND CAN NOW OFFER ADDITIVE MANUFACTURING IN A STRATASYS F170 WITH FDM TECHNOLOGY.

FDM is a manufacturing method where strong construction plastic is melted down and then laid out layer by layer. With FDM technology comes durable and strong prints that are suitable for application areas where you have to manufacture e.g. robust prototypes or lightweight parts in strong construction thermoplastics.

Material analysis

A COMMON QUESTION IN THE INDUSTRY IS IF THE MATERIAL PURCHASED MEETS THE REQUIREMENT SPECIFICATION.

If there is the wrong material in a product that has already been introduced on the market, it can be very expensive to fix and almost impossible to repair. To avoid costly problems, Merx Svenska can already in the product development phase perform independent tests of material quality from various suppliers.

Material analysis

A COMMON QUESTION IN THE INDUSTRY IS IF THE MATERIAL PURCHASED MEETS THE REQUIREMENT SPECIFICATION.

If there is the wrong material in a product that has already been introduced on the market, it can be very expensive to fix and almost impossible to repair. To avoid costly problems, Merx Svenska can already in the product development phase perform independent tests of material quality from various suppliers.